Classification of aluminum base plate: aluminum base copper clad plate is divided into three categories:

The first is a general aluminum base copper clad plate, the insulation layer is composed of epoxy glass cloth bonding sheet.

The second is high heat dissipation aluminum base copper clad plate, the insulation layer is made of high thermal conductivity epoxy resin or other resin.

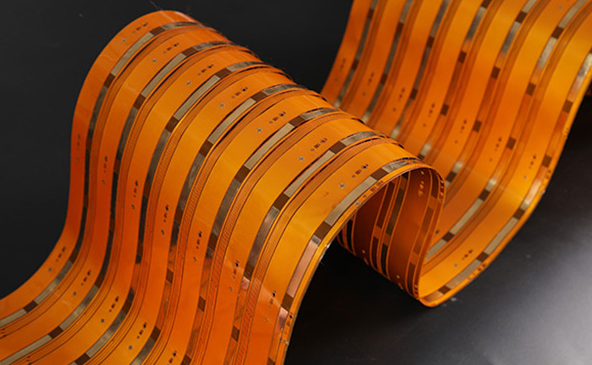

The insulation layer is composed of polyolefin resin or polyimide resin glass cloth bonded sheet. Aluminum base copper-clad plate and conventional FR-4 copper-clad plate is a big difference in heat dissipation, with 1.5mm thickness of FR-4 copper-clad plate and aluminum base copper-clad plate, the former thermal resistance 20-22. The latter thermal resistance 1.0-2.0, the latter is much smaller. V automobile brake light soft plate copper substrate and aluminum substrate difference :1, the thermal conductivity of copper substrate is twice that of aluminum substrate, the higher the thermal conductivity, the higher the heat conduction obedience, the better the heat dissipation function. 2, copper substrate can be processed into metallized holes, and aluminum substrate can not V car brake light soft plate

PCB board is generally copper substrate, which is also divided into single panel and double panel, the material used between the two is very obvious difference, aluminum plate is the main material of aluminum substrate, while THE main material of PCB board is copper. Aluminum substrate because of its SPECIAL PP material. Heat dissipation is better. The price is also more expensive. Compared with the two in terms of heat dissipation, the performance of aluminum substrate in heat dissipation is more superior to that of PCB board, and its thermal conductivity is not the same. Aluminum substrate is a kind of PCB, and the price of aluminum substrate is more expensive. 3, copper and aluminum elastic modulus difference is large, so the warpage of copper substrate and the expansion and contraction will be smaller than the aluminum substrate. Copper substrate is one of the most expensive metal substrate, thermal conductivity is many times better than aluminum substrate and iron substrate, suitable for high frequency circuit and high and low temperature variation of the ground area and precision communication equipment heat dissipation and architectural decoration industry. (2) Observe the electronic components in the circuit have no traces of high temperature, and the electrolytic capacitor has no leakage phenomenon, if so, it should be replaced. 2. Annual maintenance :(1) clean up the dust on the circuit board. (2) Spot check on the capacity of electrolytic capacitor in the circuit board. If it is found that the capacity of electrolytic capacitor is lower than 20% of the nominal capacity, it should be replaced. Generally, the life of electrolytic capacitor should be replaced for about ten years to ensure the working performance of the circuit board.

5. The patch resistance and capacitance components are easy to weld, you can first point on a solder spot tin, and then put on the end of the component, with tweezers to clamp the component, after welding a head, and then see if it is put; If it has been put straight, then weld the other end of the two in terms of heat dissipation comparison, aluminum substrate in terms of heat dissipation performance is more superior to PCB board, its thermal conductivity is not the same aluminum substrate is a kind of PCB, the price of aluminum substrate is more expensive. Aluminum substrates shall not be perforated. The coefficient of thermal conductivity of aluminum plate is aluminum plate quality evaluation is an important indicator of one of the other two most important factors are aluminum plate thermal resistance and withstand voltage value of the aluminum plate, aluminum plate in the market now generally coefficient of thermal conductivity is 2.00.1 commonly, for the coefficient of thermal conductivity of aluminum plate concrete can be measured by instruments, The e level of thermal conductivity of aluminum substrate will directly affect the price of aluminum substrate, in general, the higher the thermal conductivity of aluminum substrate is relatively higher the price of aluminum substrate. In the layout, the size of the circuit board is too large, although the welding is easier to control, but the printing line is long, the impedance increases, the anti-noise ability decreases, the cost increases; Too small, the heat dissipation decreases, welding is not easy to control, easy to appear adjacent lines interference with each other, such as the electromagnetic interference of the circuit board. Therefore, it is necessary to optimize PCB board design:

Function of SOFT PCB of V automobile brake lamp: after electronic equipment adopts printed board, due to the consistency of similar printed board, the error of manual wiring is avoided, and electronic components can be automatically inserted or mounted. Automatic soldering. Automatic detection, to ensure the quality of electronic equipment, improve the productivity of labor, reduce the cost, and facilitate the maintenance of V car brake light soft board circuit board working principle: Is the use of plate insulation material separated from the surface copper foil conductive layer, so that the current along the pre-designed route in a variety of components flow to complete such as work, amplification, attenuation, modulation, demodulation, coding and other functions. On a basic PCB, the parts are concentrated on one side and the wires are concentrated on the other. Because the wires only appear on one side, the PCB is called a single panel. A multilayer board, with multiple layers of wires, requires a proper circuit connection between the two layers, and the bridge between the circuits is called the guide hole (VIA). The basic circuit board design process can be divided into the following four steps: Development of PCB: Printed board from single-layer development to double-sided, multi-layer and flexible, and still maintain their own development trend. Due to the continuous development of high precision, high density and high reliability, and constantly reduce the volume, reduce the cost, improve the performance, making the printed board in the future electronic equipment development project, still maintain a strong vitality.

Contact: Ms.Huang

Phone: 15023181892(微信同号)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA