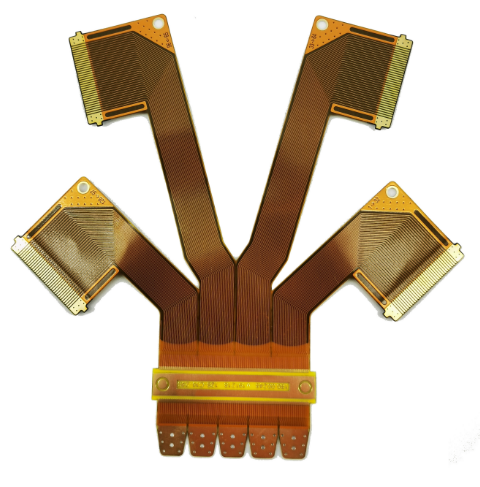

With high wiring density, light weight, thin thickness, good bending characteristics! Combined with hard and soft board (reechas Softandhardcombinationplate) - the birth and development, FPC flexible circuit and PCB plate led to the soft hard couple, this new product. Therefore, the combination of soft and hard board, is the flexible circuit board and hard circuit board, after pressing and other processes, according to the relevant process requirements combined together, formed with FPC flexible circuit characteristics and PCB characteristics of the circuit board. 3, metal base: what kind of metal insulation metal substrate, need to depend on the metal substrate thermal expansion coefficient, thermal conductivity, strength, hardness, weight, surface state and cost of comprehensive consideration of conditions such as FPC flexible circuit

(2) Observe the electronic components in the circuit have no traces of high temperature, and the electrolytic capacitor has no leakage phenomenon, if so, it should be replaced. 2. Annual maintenance :(1) clean up the dust on the circuit board. (2) spot check on the electrolytic capacitor capacity of FPC flexible line, if the capacity of electrolytic capacitor is found to be less than 20% of the nominal capacity, it should be replaced, generally the life of electrolytic capacitor should be replaced for ten years or so, to ensure the performance of the circuit board. In general, considering the cost and technical performance, aluminum plate is the ideal choice. There are 6061,5052,1060 aluminum plates available. Copper plate, stainless steel plate, iron plate and silicon steel plate can also be used if higher thermal conductivity, mechanical properties, electrical properties and other special properties are required. The discussion on the development trend of future printed board manufacturing technology at home and abroad is basically the same, that is, to high density, high precision, fine aperture, fine conductor, fine spacing FPC flexible circuit for car lights. There are pads on both sides of the double panel, mainly for connecting to other circuit boards. Although its structure is similar to that of single-layer board, the manufacturing process is very different. Its raw materials are copper foil, protective film + transparent glue. First, drill holes on the protective film according to the location requirements of the pad, and then paste the copper foil. After etching out the pad and lead, paste another protective film with a well drilled hole. , high reliability, multi-layer, high-speed transmission, light weight, thin direction development, in production at the same time to improve productivity, reduce costs, reduce pollution, adapt to the variety, small batch production direction development. The technical development level of printed circuit is generally represented by the line width, aperture, and thickness/aperture ratio on the printed board.

1, the material of the product must be AL1060, must comply with ROHS certification standards, must also be corrosion resistant. 2, the text and screen printing on the aluminum plate plate must be clear, the board must be clean and pollution-free. 3, the size of the thermal conductivity must meet the user's product performance requirements. 4, peeling strength (consistent with CCL IPC test method) 5, in accordance with the provisions of the product name specification version polarity mark and other words screen printing without error, no missing, no reprinting. , it is the final form of FPC flexible circuit of headlamp transformed from circuit schematic diagram. The related design of this part is more difficult than the design of circuit schematic diagram. We can complete the design of this part with the help of the powerful design function of ProtelDXP.

Contact: Ms.Huang

Phone: 15023181892(微信同号)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA