Foldable phones have been seen as an industry direction this year with Huawei. Samsung, Royole and others have officially released foldable phones, xiaomi. OPPO. Vivo and other manufacturers have also come up with prototypes of foldable phones. The folding phone has been turned on. The flexible circuit board is light by virtue of its weight. Thin thickness, good bending and other characteristics, become the folding hand machine indispensable components. However, FPC(flexible circuit board) application in smart phones still faces many technical difficulties, which will become the focus of current manufacturers to overcome.

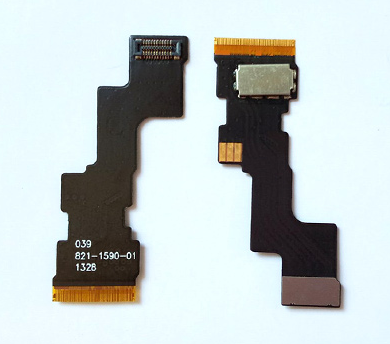

FPC is thin and light. Bendable. Winding. Foldable. The characteristics of high wiring density, perfect fit the thinness. Miniaturization of the development theme, in recent years to become PCB (printed circuit board) subdivision industry leader. Some experts said that at present in FPC, it is not difficult to achieve flexible screen, mainly lies in the display screen and PCB hard board, to achieve the folding PCB still needs a long process of research and development, for electronic materials are also very challenging.

FPC is mainly applied to mobile terminals. Consumer electronics. Automotive electronics. Industrial control. Medical. Aerospace military, etc. Among them, mobile terminal is the biggest application field of FPC, especially smart phone. It is also the field in which FPC has the highest technical capability, and will lead the technical development direction of FPC in the future. Miniaturization. Intelligent development trend will promote flexible mobile phones as a trend in the future.

Experts have also proposed solutions to the FPC requirements of folding, connecting and multiple folding screens. In mobile phones with flexible screens, due to the need to fold for many times and a large number of times, the requirements for flexible circuit boards inside mobile phones will be higher, and the corresponding use area will be further increased. However, FPC is usually manufactured by intermittent process, so it is limited by the size of production equipment. In view of this problem, experts believe that it can be extended through the middle socket, and FPC can plug and insert the gold finger to reinforce.

At present, aiming at the connection between soft plate and hard plate, the main process and technology is to make soft and hard plate. Regarding the size problem, the soft plate or soft and hard plate in the industry all use 250MM wide material, and also try to use 500MM wide material.

FPC will be an established trend in mobile applications, which also makes the FPC market a positive trend. The FPC still faces manufacturing problems, such as large applications on foldable phones. There are solutions to these problems, but they inevitably cost more. How to better control the cost of FPC, can only rely on mass production or technology upgrade to solve.

Contact: Ms.Huang

Phone: 15023181892(微信同号)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA