The customer shall first propose and provide relevant FPC soft board information to the CIRCUIT board manufacturer. The circuit board manufacturer shall give the quotation to the customer and organize the production process after both parties have no objection.

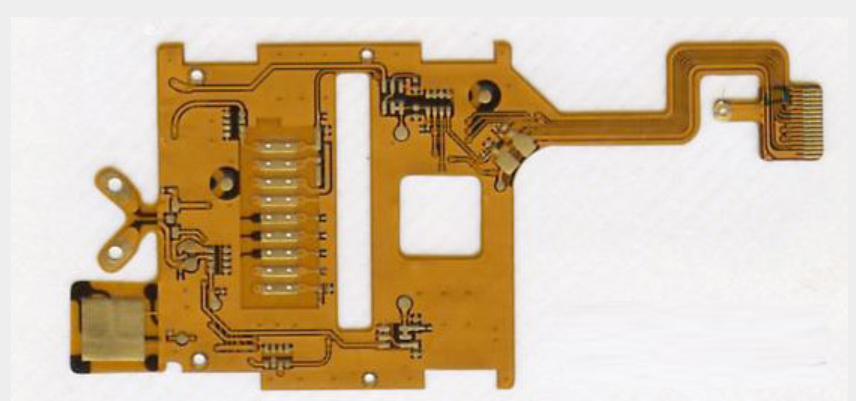

The circuit board of flexible circuit board proofing is mainly composed of pad, through hole, mounting hole, wire, components, connectors, filling, electrical boundary circuit board industrial area, etc. The main functions of each component are as follows:

Pad: Metal hole used to weld pins of components.

Perforation: there are metal perforation and non-metal perforation, among which the metal perforation is used to connect the pins of components between layers.

Mounting hole: Used to fix the circuit board.

Wire: Copper film of electrical network used to connect component pins.

Connectors: Components used to connect circuit boards.

Filling: Used for copper coating of ground wire network, which can effectively reduce impedance.

Electrical boundary: Used to determine the dimension of the board beyond which all components on the board must not exceed this boundary.

Flexible circuit board proofing products are divided into the following three types:

Single panel: On a basic PCB board, the parts are concentrated on one side and the wires are concentrated on the other. Because the wire appears on only one side, we call this type of PCB board single-sided. Because single panels had many strict restrictions on the design of the circuit (because there was only one side, the wiring could not be crossed and had to be routed in a separate path), only early circuits used such boards.

Dual panel: The circuit board has wiring on both sides. But in order to use both wires, there must be proper electrical connections between the two sides. This "bridge" between circuits is called a guide hole (VIA). Guide holes are small holes in the PCB board that are filled or coated with metal and can be connected to wires on both sides. Because a dual panel has twice the area of a single panel, and because the wiring can be interlaced (it can be wound around to the other side), it is better for more complex circuits than a single panel.

Multi-layer board: when multi-layer board is required in complex application, the circuit can be arranged into multi-layer structure and pressed together, and the through-hole circuit is built between layers to connect each layer circuit. The copper foil substrate of the inner line is cut to the size suitable for processing and production. Before pressing the film on the substrate, the copper foil on the surface should be roughened properly by means of brushing, micro-etching, etc., and then the dry film photoresist is tightly attached to it at appropriate temperature and pressure. The substrate with good dry film photoresist is sent into the uv exposure machine, and the photoresist will produce polymerization reaction after the uv irradiation in the transmittance area of the film (the dry film in this area will be retained as an etching inhibitor in the later development and copper etching steps), and the line image on the film is transferred to the dry film photoresist on the board. After the protective film on the film surface is torn off, the unilluminated area on the film surface is firstly removed by developing sodium carbonate aqueous solution, and then the exposed copper foil is corroded and removed with hydrochloric acid and hydrogen peroxide mixed solution to form the circuit. Finally, sodium hydroxide aqueous solution was used to remove the successful dry film photoresist. For the inner circuit board with more than six layers (including), the automatic positioning punching machine can rush out the rivet reference hole of the line alignment between layers. In order to increase the area that can be wired, more single - or double-sided wiring boards are used. The multilayer board uses several double panels, and a layer of insulation is placed between each panel and glued (pressed). The number of layers of the board represents several independent wiring layers, usually an even number of layers, including the outermost two layers. Most motherboards are built with four to eight layers, but technically close to 100 layers of PCB boards are possible. Most large supercomputers use quite a few layers of motherboards, but they have fallen out of use as they can be replaced by clusters of ordinary computers. Because the layers in a PCB are so tightly integrated, it's not always easy to see the actual number, but if you look closely at the motherboard, you might be able to. With the introduction of surface mount technology, the automatic detection technology of circuit board is applied, and the package density of circuit board increases rapidly. Therefore, automatic inspection of circuit boards is not only essential, but also economical, even for low density and average number of circuit boards. In the complex circuit board inspection, two common methods are the needle bed test method and the double probe or flying needle test method.

In the FPC factory, the circuit board proofing process is generally according to the above operations, but each FPC sample product will change according to the difficulty of production.

Contact: Ms.Huang

Phone: 15023181892(微信同号)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA