Circuit board (PCB) alias: circuit board, PCB board, aluminum substrate, HF board, ultra-thin circuit board, ultra-thin circuit board, printing (copper etching technology) circuit board and so on. Because of current electron production

Products are constantly micro with fine, circuit board can make circuit miniaturization, intuitive, for fixed circuit mass production and optimization with electrical layout plays an important role, so the application

And more widely.

Aluminum substrate is a kind of copper clad metal plate with good heat dissipation function. Generally, a single panel is composed of three layers, which are circuit layer (copper foil), insulation layer and gold

At the grass-roots level. Common in LED lighting products ultra-thin aluminum substrate has positive and negative sides, the white side is welded LED pin, the other side presents aluminum color, generally coated with thermal coagulation and

Thermal part contact. There are ceramic substrates and so on.

Advantages of aluminum substrate:

1, more suitable for SMT process.

2. Meet RoHs requirements.

3, the heat dissipation through the effective treatment, so as to reduce the module operating temperature, prolong the service life, improve reliability; 7, 3M adhesive paper - mainly used for 0.4mm and above thickness OF FR4 and FPC paste, as well as FPC and customer product assembly fixed, the use of FPC auxiliary materials, ultimately according to the customer's use of the environment and functional requirements to determine the ultra-thin aluminum substrate.

4. As the volume decreases, the assembly area of radiator and other hardware (including thermal interface materials) is reduced, the product volume is reduced, and the cost of hardware and assembly is reduced.

5. Good mechanical endurance, compared with some simple process to make ceramic circuit boards. Disadvantages of aluminum substrate :1. High cost: compared with other affordable goods, aluminum substrate

The price of more than 30% of the product price is not in line with the standard. 2. At present, the mainstream can only do single panel, and it is difficult to do double panel technology: at present, the domestic are single panel

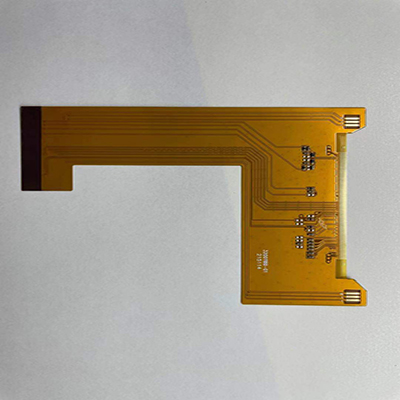

Have to be more skilled, the process and technology of multi-layer board is more mature abroad, there are more people to understand. FPC circuit board is classified according to its medium and structure.

The arrangement is as follows: 1. Single-layer soft board structure FPC circuit board The flexible board of this structure is the most simple flexible board. This is usually the base material + transparent adhesive + copper foil is a set of bought original material

Material, of course, protective film + transparent adhesive is another kind of raw materials bought.

In recent years, flexible circuit board (FPC) has become one of the fastest growing sub-industries in the printed circuit board industry. IDTechEx predicts flexible circuits by 2020

The market size of FPC will grow to us $26.2 billion. (1) Schematic design of circuit -- schematic design of circuit is mainly made use of ProtelDXP schematic design

To draw the schematic diagram. (2) Generate network report -- network report is to display the circuit principle and the link relationship of various components of the report, it is the connection of circuit schematic design and

The bridge and link of circuit board design, through the network report of circuit schematic diagram, can quickly find the connection between components, so as to provide convenience for PCB design. The soft

How to weld sex circuit board? What do you need to pay attention to? Flexible circuit board welding procedure: 1. Before welding, apply flux on the pad and handle with a soldering iron

Times, so as not to solder plate bad or oxidation, resulting in bad welding, chip is generally not need to deal with.

Contact: Ms.Huang

Phone: 15023181892(微信同号)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA