Mark points, also known as reference points, provide a common locatable circuit pattern for all steps in the FPC flexible plate assembly process. Therefore, Mark points are critical to SMT production. All SMT SMT boards must have Mark points, so what should we pay attention to when designing? The following xiaobian will explain it in detail.

Notes for designing Mark points

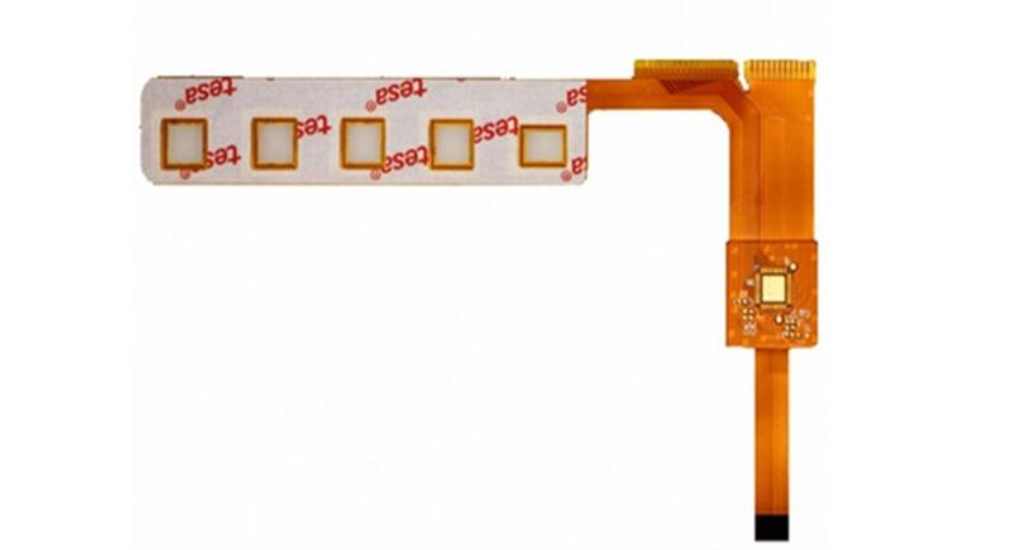

1. The shape requires Mark point to be marked as solid circle; A complete Mark point consists of Mark points (or feature points) and empty areas. The minimum diameter of Mark Mark is 1.0mm, and the maximum diameter is 3.0mm. The size change of Mark Mark on the same printed board cannot exceed 25um.

What should be noted about Mark point in FPC flexible board design

2.Mark points are positioned diagonally opposite to each other on the circuit board or composite board as far apart as possible. The best distribution is in the longest diagonal position; To ensure SMT SMT accuracy, the FPC flexible circuit board must have at least one pair of Mark points that meet the design requirements and can be recognized by THE SMT machine, that is, there must be a single Mark.

3.Mark point (edge) distance from the edge of the printed board must be greater than or equal to 5.0mm(minimum FPC spacing required by machine clamping), and must be within the FPC board rather than at the edge of the board, and meet the minimum Mark point emptiness requirements. Emphasis: the distance between Mark point edge and plate edge ≥5.0mm, not Mark point center.

4. There must be an empty area around the Mark Mark without other circuit features or marks. The radius of the circle in the open area is r≥2R, and r is the radius of Mark point. When r reaches 3R, the machine recognition effect is better. It is often found that the open area of Mark point is blocked by character layer or CUT by V-cut, resulting in the inability of SMT machine to recognize.

5.Mark marks may be bare copper, bare copper protected with a clear anti-oxidation coating, nickel or tin plating, or solder coating. The surface flatness of Mark Mark should be within 15um. The best performance is achieved when there is a high contrast between the Mark Mark and the substrate material of the printed board. The inner background of all Mark points must be the same.

The above is about the "FPC soft board design Mark points for attention", hope to help you, if there is no clear place, please contact our customer service for you to answer.

Contact: Ms.Huang

Phone: 15023181892(微信同号)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA