What is PCB board :PCB board generally refers to printed circuit board. Printed circuit boards (PCB boards), also known as printed circuit boards, are providers of electrical connections to electronic components. Its development has a history of more than 100 years; Its design is mainly layout design; The main advantage of using circuit board is to greatly reduce wiring and assembly errors, improve the level of automation and production labor rate. According to the number of PCB layers, it can be divided into single-sided FPC circuit board, double-sided FPC circuit board, four-layer FPC circuit board, six-layer FPC circuit board and other multi-layer FPC circuit board. Because the printed circuit board is not a general terminal product, so the definition of the name is slightly confused, for example: the mother board used by personal computers, called the motherboard, and can not be directly called the circuit board, although there is a circuit board in the host board, but not the same, so the evaluation of the industry when the two related but can not say the same. Another example: because there are integrated circuit parts loaded on the circuit board, so the news media called him IC board, but in fact he is not equal to the printed circuit board. We usually say the printed circuit board refers to the bare board - that is, no board components. Soft lamp with FPC3, made of products in electrical strength and pressure is more prone to problems: this problem is mainly related to the material itself. 4, aluminum base in the pressure index of the plate will cause the impact of substandard; The pressure resistance of the whole lamp and aluminum substrate is not up to standard; Influence of circuit design and structure design on voltage resistance

, and some aluminum substrates applied in LED lights in the market actually can not withstand 800V. So aluminum substrate is not a good soft lamp with FPC circuit board 2. In the production of aluminum substrate process between the operation personnel must be light, so as to avoid the surface is scratched. 3. In the production process, operators should avoid using their hands to touch the effective area of the aluminum substrate as far as possible, tin spraying and later process holding plate only allowed to hold the plate edge, is prohibited to touch the plate directly with their fingers. 4. Aluminum base plate is a special plate, its production should be caused by each district and each process attaches great importance to, section leader, foreman personally to the quality, to ensure the smooth production of the plate in each process. The maintenance of the circuit board in use, should be regular maintenance, to ensure that the circuit board work in a good state and reduce the failure rate of the circuit board soft lamp belt

1, the material of the product must be AL1060, must meet ROHS certification standards, must also be corrosion resistant. 2, the text and screen printing on the aluminum plate plate must be clear, the board must be clean and pollution-free. 3, the size of the thermal conductivity must meet the user's product performance requirements. 4, peeling strength (consistent with CCL IPC test method) 5, in accordance with the provisions of the product name specification version polarity mark and other words screen printing without error, no missing, no reprinting. The maintenance of the circuit board in use is divided into the following situations: 1, half a year maintenance: (1) every quarter to clean the dust on the circuit board, the circuit board can be cleaned with special cleaning liquid, the dust on the circuit board is cleaned, and the circuit board can be blown dry with a hair dryer.

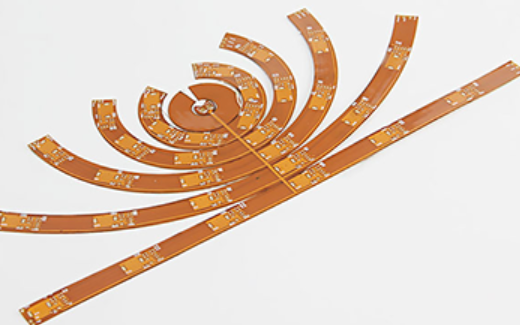

In summary, in recent years, the market of consumer electronic products led by smart phones, tablet computers and other mobile electronic devices has grown rapidly. Equipment miniaturization, thin and thin trend is becoming more and more obvious soft lamp with FPC CIRCUIT board (1) circuit schematic diagram design - circuit schematic diagram design is mainly using ProtelDXP schematic editor to draw schematic diagram. (2) generate reports - network statement that shows the links of all components in the circuit principle and relationship of the report, it is connected to circuit schematic design and circuit board design of bridge and link, through the network statements circuit schematic diagram, can quickly find the components, the relation between which provide convenience for the back of the PCB design. As a result, traditional PCB has been unable to meet the requirements of the product, so major manufacturers began to study new technology to replace PCB, and FPC circuit board as the most favored technology, is becoming the main connection accessories of electronic equipment.

Contact: Ms.Huang

Phone: 15023181892(微信同号)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA