What is PCB board :PCB board generally refers to printed circuit board. Printed circuit boards, also known as printed circuit boards, are providers of electrical connections to electronic components. Its development has a history of more than 100 years, and its design

Mainly layout design, the main advantage of using circuit board is to greatly reduce wiring and assembly errors, improve the level of automation and production labor rate. According to the number of circuit board layers can be divided into single panel, double panel, four layer board, six layer board

And other multilayer circuit boards. Since printed circuit boards are not general end products, there is some confusion in the definition of the name, for example: the mother board used by personal computers, called the motherboard, and cannot be directly called the board, although the host

There are circuit boards in the board, but they are not the same, so when evaluating the industry they are related but not the same. Another example: because there are integrated circuit parts loaded on the circuit board, so the news media called it an IC board, but in essence

Nor is it equivalent to a printed circuit board. We usually say the printed circuit board refers to the bare board - that is, no board components. FPC circuit board (3) For high-power devices coated with thermal silicon grease, check whether the thermal silicon grease is dry and solid

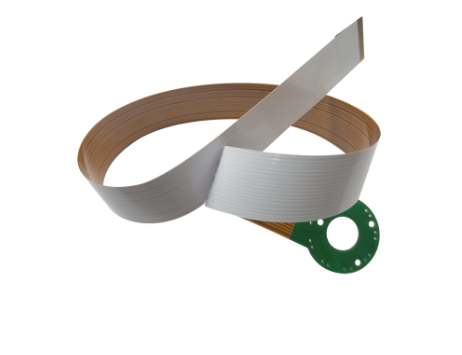

FPC PCB

Aluminum substrate is generally placed on the patch device tube output rectifier tube through the substrate to conduct the heat out, the thermal resistance is very low, can achieve high reliability. The transformer adopts flat patch structure, and can also heat the heat through the substrate, and its temperature rise is higher than that of the conventional

To be low, the same specification transformer using aluminum substrate structure can get larger output power. Due to the excellent thermal conductivity of the aluminum substrate, it is difficult to weld in a small amount of manual welding, and the solder cools too fast, which is prone to problems

Practical method, an ordinary iron for ironing clothes (preferably with temperature adjustment function), turn over, ironing face up, fixed, the temperature to 150 degrees Celsius or so, put the aluminum plate on the iron, heating for a period of time, and then

According to the conventional method to attach and weld the components, the temperature of the iron is appropriate to the device is easy to weld, too high may be damaged, or even aluminum substrate copper peel, the welding effect is not good, the temperature is too low, to be flexible

After the dry and solid heat dissipation grease is removed, new heat dissipation grease should be coated to prevent the high-power components in the circuit board from burning out due to poor heat dissipation. Special detection method of aluminum base copper clad plate, one is the measurement of dielectric constant and dielectric loss factor

Method, for the variable Q value series resonance method, the sample and the tuned capacitor connected to the high-frequency circuit in series, measuring the Q value of the series circuit; The second is the thermal resistance measurement method, to calculate the ratio of temperature difference between different temperature measurement points and thermal conductivity, aluminum substrate

Process refers to the principle of advanced technology and reasonable economy, with the final product quality as the purpose, to develop reasonable and feasible specifications for the processing and treatment of aluminum substrate. Ensure smooth production process.

FPC circuit board 1, FR4- hard texture, different thickness of 0.15-2.0mm, mainly used in FPC welding at the opposite side, as reinforcement, convenient welding stability and reliability; Fr-4 is a fire resistant material grade code circuit board: in

On an insulating substrate, a printed board formed to a predetermined design to connect wires from point to point, but without printed elements. Circuit board: on an insulating base material, a predetermined design is formed to connect wires from point to point and print components

Plate.

Generally speaking, the circuit board is already equipped with various components of the board, and the circuit board is not equipped with components, just a good design of the substrate. There is no difference between a circuit board and a circuit board, essentially the same. Represented by the

It is not a material name, but a material grade, so the current general circuit board used fr-4 grade material has a lot of

But most are composites made from what's called tera-function epoxy with Filler and glass fiber.

1. Audio equipment: input, output amplifier, balance amplifier, audio amplifier, preamplifier, power amplifier, etc. 2. Power supply equipment: switching regulator, DC/AC converter, SW regulator and other medical treatment

Generally speaking, FPCPCB board is copper substrate, which can also be divided into single panel and double panel. The materials used between the two are obviously different. The main material of aluminum substrate is aluminum plate, while the main material of PCB board is copper and aluminum base

Board because of its SPECIAL PP material. Heat dissipation is better, the price is more expensive. Compared with the two in terms of heat dissipation, the performance of aluminum substrate is more superior to that of PCB board in terms of heat dissipation, and its thermal conductivity is also different

A kind of, the price of aluminum substrate is more expensive. 3. Communication electronic equipment: high frequency amplifiers, filter appliances, transmitting circuits. 4. Office automation equipment: motor drivers, etc. 5. Automobile: electronic regulator, igniter, power control

And etc. 6. Computer: CPU board, floppy disk drive, power supply unit, etc.

Contact: Ms.Huang

Phone: 15023181892(微信同号)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA