1. Flexibility and reliability of FPC flexible circuit board

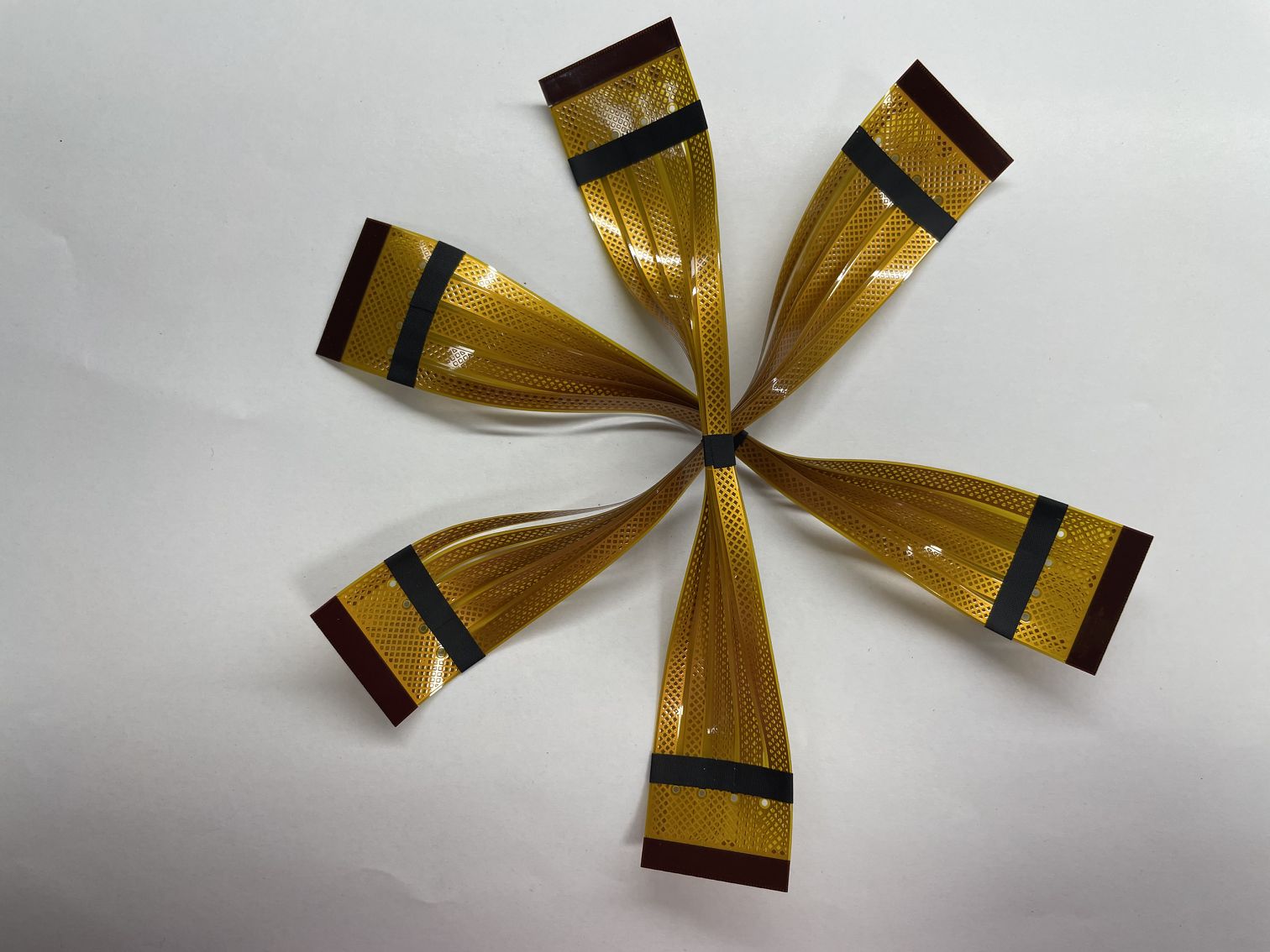

At present, there are four kinds of FPC flexible circuit board: single-sided, double-sided, multi-layer FPC flexible circuit board and rigid flexible circuit board.

① Single-sided FPC flexible circuit board is the lowest cost, when the electrical performance is not high requirements of the printed board. When wiring on one side, one side flexible circuit board should be used. It has a layer of chemically etched conductive pattern, and the conductive pattern layer on the flexible insulating substrate is calendered copper foil. Insulating substrates may be polyimide, polyethylene terephthalate, aromatic amide fibre ester and polyvinyl chloride.

The double-sided FPC flexible circuit board is a conductive graph made of a layer etched on both sides of the insulating base film. Metallized holes connect the shapes on both sides of the insulating material to form conductive paths to meet the design and use of flexure. And the covering film can protect the single and double - sided wire and indicate the position of the element.

The multi-layer FPC flexible circuit board is composed of 3 or more layers of single-sided or double-sided flexible circuit lamination together, through drilling hole L, electroplating to form metallized holes, forming conductive paths between different layers. In this way, there is no need to use complex welding process. Multilayer circuits have huge functional differences in higher reliability, better thermal conductivity and easier assembly performance. The interaction of assembly size, number of layers and flexibility should be considered when designing the layout.

(4) The traditional rigid FPC flexible circuit board is composed of rigid and flexible substrate with selective formation pressure. Tight structure with metallized arch L forming conductive connection. If a printed board has components on both sides, rigid flexible circuit boards are a good choice. But if all the components are on one side, it is more economical to use a double-sided flexible circuit board with a layer of FR4 reinforcement on the back.

The FPC flexible circuit board with mixed structure is a kind of multilayer board, and the conductive layer is composed of different metals. An 8-layer board uses FR-4 as the inner layer medium and polyimide as the outer layer medium, with leads extending in three different directions from the motherboard, each of which is made of a different metal. Constantan alloy, copper and gold are used as independent leads. This kind of hybrid structure is the only feasible solution when the relation between electric signal conversion and heat conversion and the electrical performance is harsh at low temperature.

It can be evaluated by the convenience and total cost of the interconnect design to achieve the best price-performance ratio.

2. Economy of flexible circuit

If the circuit design is relatively simple, the total volume is not large, and the space is suitable, the traditional interconnecting method is mostly much cheaper. Flexible circuits are a better design choice if the circuit is complex, handles many signals, or has special electrical or mechanical performance requirements. Flexible assembly is most economical when the size and performance of the application exceed the capabilities of rigid circuits. A 12mil pad with 5mil through hole and a flexible circuit with 3mil lines and spacing can be made on a thin film. Therefore, it is more reliable to mount the chip directly on the thin film. Because it does not contain flame retardants that could be a source of ion drill contamination. These films may be protective and cure at higher temperatures, resulting in higher vitrification temperatures. Flexible materials are cheaper than rigid materials because connectors are eliminated.

The high cost of raw materials is the main reason for the high price of flexible circuits. The cost of raw materials for the lowest polyester flexible circuit is 1.5 times that of the rigid circuit. High-performance polyimide flexible circuits are up to 4 times or more. At the same time, the flexibility of the material makes it difficult to carry out automatic processing in the manufacturing process, resulting in the reduction of output; Defects are prone to occur in the final assembly process, including peeling of flexible accessories and line breakage. This is more likely to happen when the design is not suitable for the application. Under high stresses caused by bending or molding, reinforcement or reinforcement materials are often selected. Despite the high cost of raw materials, the folding, bendable and multi-layer splitter feature will reduce the overall size of the components and thus the amount of materials used, reducing the total assembly cost.

The flexible circuit industry is in a small but rapid development. Polymer thick film process is a high efficiency and low cost production process. The process selectively prints conductive polymer inks on a cheap, flexible substrate. Its representative flexible substrate is PET. Polymer thick film conductor includes silk screen metal filler or carbon filler. The polymer thick film process itself is clean and uses lead-free SMT adhesives that do not have to be etched. Polymer thick film circuit is 1/10 the price of copper polyimide thin film circuit because of its addition process and low cost of substrate. Is the price of rigid circuit board 1/2 ~ 1/3. The polymer thick film method is especially suitable for equipment control panels. In mobile phones and other portable products, the polymer thick film method is suitable for converting components, switches and lighting devices on printed circuit boards into polymer thick film circuits. It saves costs and reduces energy consumption.

Generally speaking, flexible circuit is indeed more expensive than rigid circuit, the cost is higher.When flexible circuit boards are manufactured, in many cases they have to face the fact that many parameters are outside the tolerance range. The difficulty of making flexible circuits lies in the flexibility of materials.

3. Cost of flexible circuit

Despite these cost factors, the price of flexible assemblies is falling and becoming closer to that of traditional rigid circuits. The main reasons are the introduction of newer materials, improved production processes and structural changes. The current structure allows for higher thermal stability and fewer material mismatches. Some newer materials allow for more precise lines with thinner copper layers, making components lighter and more suitable for fitting into smaller Spaces. In the past, copper foil was glued to a media coated with adhesive by rolling process. Now, copper foil can be generated directly on the media without adhesive. These techniques can produce layers of copper several microns thick and precise lines of 3 meters. 1 or narrower. The flexible circuit has flame retardant property after removing some adhesives. This will speed up the uL certification process and further reduce costs. Flexible circuit board solder masks and other surface coatings further reduce the cost of flexible assembly.

In the coming years, smaller, more complex and more expensive flexible circuits will require more innovative approaches to assembly and the addition of hybrid flexible circuits. The challenge for the FPC flexible circuit board industry is to take advantage of its technological advantages to keep pace with computers, telecommunications, consumer demand, and dynamic markets. In addition, flexible circuit will play an important role in the lead-free operation.

Polly peak circuit board as a professional FPC flexible circuit board manufacturers, we are in the direction of the digital camera, car satellite positioning device, liquid crystal TV, notebook computer, medical instrument, intelligent robot, mobile phone and so on are involved in the communication field and research and development, thank you very much for support of numerous customers to polly peak, willing to work with us hand in hand advance together, Welcome more customers to negotiate cooperation.

Contact: Ms.Huang

Phone: 15023181892(微信同号)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA