Advantages of aluminum substrate PCB: A loose. Heat is significantly better than standard FR-4 structures. B. The dielectric used is usually 5 to 10 times the thermal conductivity of conventional epoxy glass and 1/10 of the thickness. The heat transfer index is more efficient than traditional rigid PCBS. D. You may use copper weights lower than those shown on IPC recommended charts. Audio equipment: input amplifier, output amplifier, balance amplifier, audio amplifier, preamplifier, power amplifier, etc. 2. Power supply equipment: switching voltage regulator 'DC/AC converter SW voltage regulator, etc. Laser head treatment line plate what is aluminum substrate: Aluminum substrate is a metal base copper-clad plate with good heat dissipation function. Generally, a single panel is composed of three layers, which are circuit layer (copper foil). Insulation layer and metal base laser head treatment line

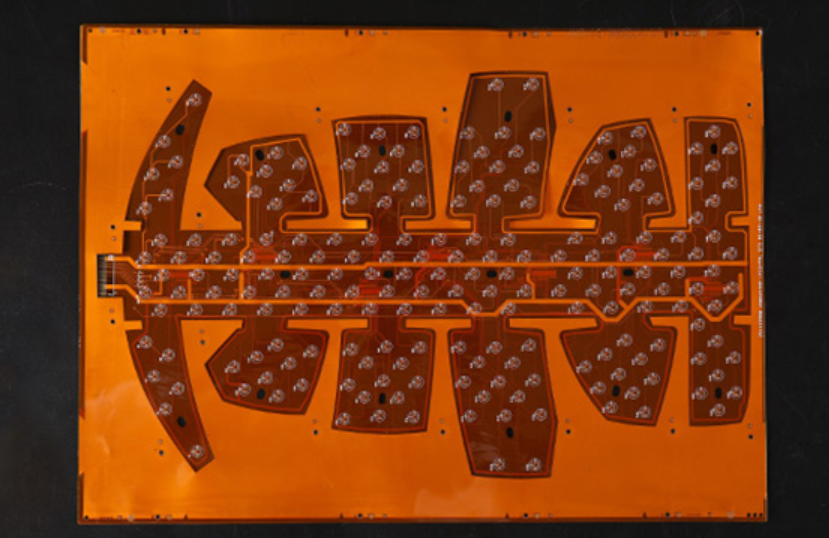

The working principle of the strip board is to separate the surface copper foil conductive layer from the base insulation material, so that the current flows along the pre-designed route in various components, such as doing work. Amplification. Attenuation. Modulation. Demodulation. Coding and other functions. On a basic PCB, the parts are concentrated on one side and the wires are concentrated on the other. Because the wires only appear on one side, the PCB is called a single panel. Multilayer plate. The layers have wires and must be properly connected by a circuit between the two layers. The bridge between the circuits is called the guide hole (VIA). The basic circuit board design process can be divided into the following four steps: common in LED lighting products. There are positive and negative sides, the white side is welded LED pin, the other side is aluminum color, generally daub heat conduction paste and heat conduction part contact. There are ceramic substrates and so on. The development trend of PCB manufacturing technology at home and abroad is basically the same, that is to high density. High precision. Fine aperture. Thin wire. Thin pitch laser head treatment line plate

(2) Observe the electronic components in the circuit have no traces of high temperature, and the electrolytic capacitor has no leakage phenomenon, if so, it should be replaced. 2. Annual maintenance :(1) clean up the dust on the circuit board. (2) Spot check on the capacity of electrolytic capacitor in the circuit board. If it is found that the capacity of electrolytic capacitor is lower than 20% of the nominal capacity, it should be replaced. Generally, the life of electrolytic capacitor should be replaced for about ten years to ensure the working performance of the circuit board. High reliability. Multi-layer. High speed transmission and light weight. Thin direction development, in production at the same time to improve productivity, reduce costs, reduce pollution, adapt to the variety, small batch production direction development. The technical development level of printed circuit is generally represented by the line width, aperture, and thickness/aperture ratio on the printed board.

1. Audio device: Input. Output amplifier. Balanced amplifier. Audio amplifier. Preamplifier. Power amplifier, etc. 2. Power supply: switch regulator. DC/AC converter. A patch device is generally placed on the aluminum substrate of laser head therapy wiring plate such as SW regulator. The tube and output rectifier tube conduct heat out through the substrate, and the thermal resistance is very low, which can achieve high reliability. The transformer adopts plane patch structure, but also through the substrate heat dissipation, the temperature rise is lower than the conventional, the same specification transformer adopts aluminum substrate structure can get larger output power. Due to excellent thermal conductivity aluminum plate, difficult in small amount of manual welding, solder cooling too fast, easy problems existing a simple and practical method, will be a common electric iron used ironing temperature adjustment function is), turn it over, ironing, oriented fixed well, the temperature to 150 ℃ or so, put the aluminum plate on top of the iron, heating time, Then stick the components and welding in accordance with the conventional method, the temperature of the iron is suitable for easy welding of the device, too high may be damaged when the device, or even aluminum plate copper peel, the temperature is too low, the welding effect is not good, to be flexible. 3. Communication electronic equipment: high frequency amplifiers, filter appliances, transmitting circuits. 4. Office automation equipment: motor drivers, etc. 5. Car: Electronic regulator. Igniter. Power controller, etc. 6. Computer: CPU board. Floppy disk drives, power supply units, etc.

Contact: Ms.Huang

Phone: 15023181892(微信同号)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA