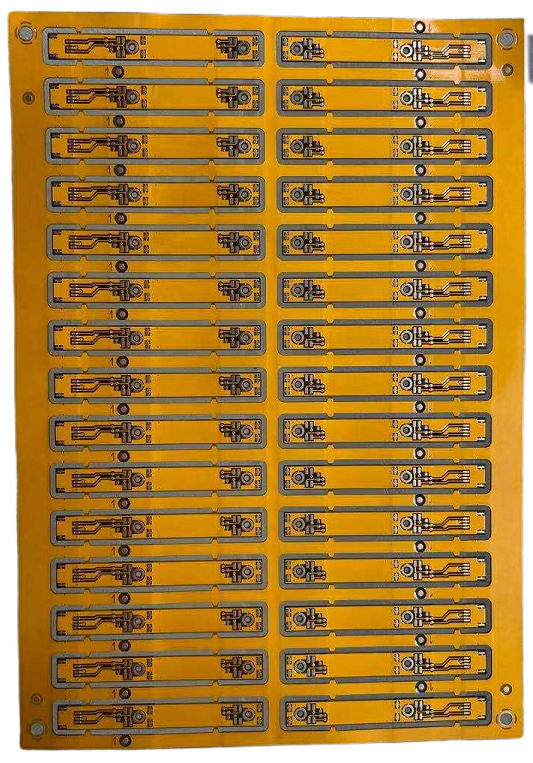

FPC flexible circuit board is a highly reliable and excellent flexible printed circuit board made of polyimide or polyester film as the base material, referred to as soft board or FPC, with high wiring density, light weight, thin thickness, can be freely bent, folded, winding, can move and expand freely in three-dimensional space; Good heat dissipation performance, can use FPC to reduce the volume; Can realize lightweight, miniaturization, thin, so as to achieve the integration of components and wire connection.

FPC soft plate because of its light, thin and irregular shape and other reasons, molding can not be used in the way of gongs plate, and laser is not suitable for mass production because of low efficiency, so in mass production, can only use die cutting.

FPC soft plate punching common problems:

1, partial

A. Artificial reasons (hole tightness will deformation hole during positioning)

B. Cut the plate to the positioning hole

C. Cover the hole when sticking auxiliary material

2, crushed

A, blanking die compression injury

B. Clean the mold when it is not determined

3, become warped copper

A, slow speed, low pressure

B, die edge is not sharp

4. Impact back: the direction of the feed is wrong.

Key points of FPC soft plate punching operation control:

1, cutting plate must be aligned with the cutting line

2, self-test can not have serious burr or pull, tear and abnormal concave and convex point, residual glue, reinforcing offset, off the paper.

3, pay special attention to the mold version should be consistent with the requirements.

4, the impact deviation must be within the tolerance, the measurement of excess tolerance to repair mold OK before production.

Contact: Ms.Huang

Phone: 15023181892(微信同号)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA