1. Single-sided flexible circuit board

Lowest cost. When the electrical performance requirements are not high, and can be single-side wiring, the single-side flexible circuit board should be used. This most common form has found commercial applications, such as ink cartridges for printers and memory for computers. The single flexible plate has a layer of chemically etched conductive pattern, and the conductive pattern layer on the flexible insulating substrate is calendered copper foil. Insulating substrates used for flexible assembly can be polyimide (Kapton), polyethylene terephthalate (PET), aromatic amide fiber paper (Nomex) and polyvinyl chloride (PVC).

2. Double-sided flexible circuit board

A double-sided flexible circuit board is a conductive pattern etched on each side of the substrate film. Metallized holes connect the shapes on both sides of the insulating material to form conductive paths to meet the design and use of flexure. And the covering film can protect the single and double - sided wire and indicate the position of the element.

3. Multi-layer flexible circuit board

Multi-layer flexible circuit board is three or more layers of single-sided flexible circuit board or double-sided flexible circuit board laminated together, through drilling, electroplating to form a metallized hole, in different layers to form a conductive path. In this way, there is no need to use complex welding process. Although the number of conductive layers designed to be of this flexible type can be unlimited, the interaction of assembly size, layers and flexibility should be taken into account when designing the layout to ensure convenient assembly.

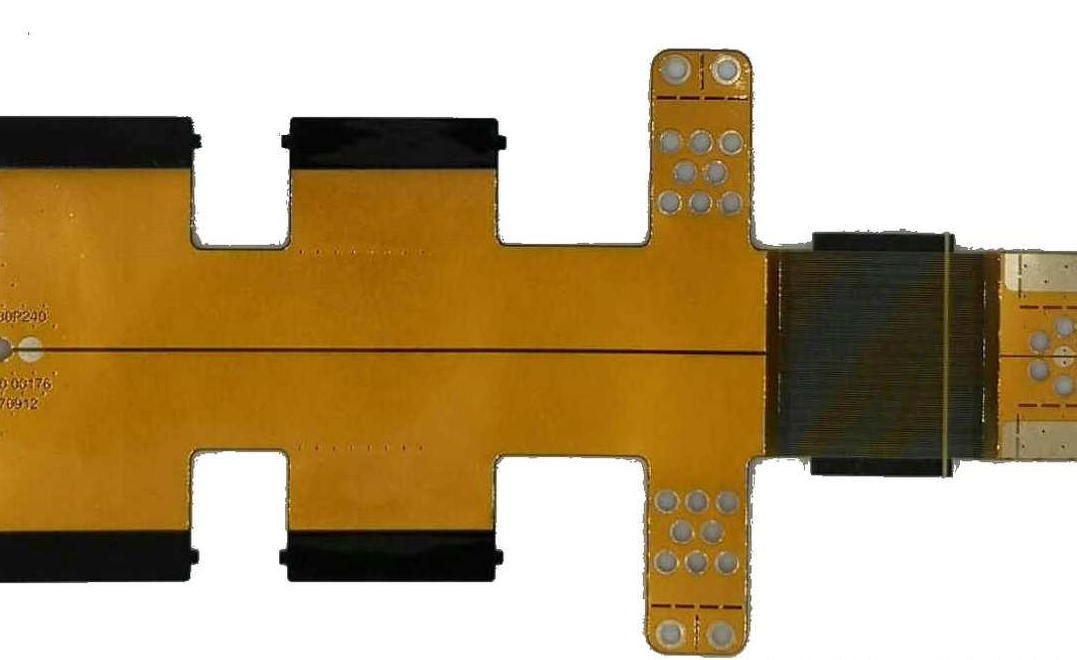

4. Rigid-flex combination

Traditional rigid flexible plates are composed of rigid and flexible substrates pressed together by selective layers. Compact structure with conductive connections formed by metallized holes. For reliability and price considerations, manufacturers should try to keep as few layers as possible.

Four kinds of flexible circuit boards are common

HDI rigid-flexible board: High Density Interconnection (HDI) rigid-flexible printed circuit board is a high-end printed circuit board product. Its goal is to meet the growing needs of electronic products toward miniaturization, High frequency, High speed and multi-function. HDI rigid flexible combined board has the advantages of popular HDI board and rigid flexible combined board, which promotes the high integration and high intelligence growth of electronic system design and production. It has been widely used in high-end electronic products such as aerospace skills, medical equipment and cost.

What is PCB board :PCB board generally refers to printed circuit board. Printed circuit boards (PCB boards), also known as printed circuit boards, are providers of electrical connections for electronic components. Its development has been more than 100 years; Its design is mainly layout design; The main advantage of using circuit board is to greatly reduce wiring and assembly errors, improve the level of automation and production labor rate. According to the number of PCB layers, it can be divided into single panel, double panel, four layer board, six layer board and other multi-layer PCB. Because the printing combination of soft and hard board is not a general end product, so the definition of the name is slightly confused, for example: the mother board used by personal computers, called the motherboard, and can not be directly called the circuit board, although the mainframe board has the existence of circuit board, but not the same, so the evaluation of the industry when the two related but can not say the same. For example: because there are integrated circuit parts loaded on the circuit board, so the news media called him IC board, but in essence he is not equivalent to printing circuit board. We usually say the printed circuit board refers to the bare board - that is, no board components on the circuit board. 1. Aluminum base plate is a very precious metal material, so in the production process, we must pay attention to the standardization of operation, to avoid the elimination of aluminum base material waste because of non-standard operation. Aluminum substrate is a kind of metal base copper clad plate with good heat dissipation function. Generally, a single panel is composed of three layers, which are respectively circuit layer (copper foil), insulation layer and metal base. For high-end use, there are also double panels designed for circuit layer, insulation layer, aluminum base, insulation layer, circuit layer. A few applications for multilayer board, can be made of ordinary multilayer board and insulation layer, aluminum paste. Aluminum substrate and PCB board difference:

5. The patch resistance and capacitance components are relatively easy to weld, you can first point tin on a solder joint, and then put on the end of the component, with tweezers to clamp the component, after welding a head, and then see whether it is put right; If it has been put, then welding on the other end of the classification of aluminum substrate: aluminum clad copper plate is divided into three categories: one is a universal aluminum clad copper plate, the insulation layer is composed of epoxy glass cloth bonding sheet; The second is high heat dissipation aluminum base copper clad plate, the insulation layer is composed of high heat conduction epoxy resin or other resin; The insulation layer is composed of polyolefin resin or polyimide resin glass cloth bonded sheet. Aluminum base copper clad plate and conventional FR-4 copper clad plate is a big difference in heat dissipation, compared with 1.5mm thickness OF FR-4 copper clad plate and aluminum base copper clad plate, the former thermal resistance 20-22, the latter thermal resistance 1.0-2.0, the latter is much smaller. In the layout, the size of the circuit board is too large, although the welding is easier to control, but the printing line is long, the impedance increases, the anti-noise ability decreases, the cost increases; Too small, the heat dissipation decreases, welding is not easy to control, easy to appear adjacent lines interference with each other, such as the electromagnetic interference of the circuit board. Therefore, PCB board design must be optimized:

Medical FPC production process is complex, from cutting and drilling to packaging and shipping, there are more than 20 processes needed in the middle. In this long production process, according to customer demand, a variety of auxiliary medical FPC1 will be used. The material must be AL1060, must meet ROHS certification standards and must be corrosion resistant. 2. The text and screen printing on the aluminum plate plate must be clear, and the board must be clean and pollution-free. 3. The size of the thermal conductivity must meet the user's product performance requirements. 4. Peeling strength (consistent with CCL IPC test method) 5. Screen printing of product name, specification, version, polarity mark and other words shall be carried out in accordance with the provisions without error, omission or reprinting. The base material of the soft and hard bonded board is generally double-sided or single-sided copper foil, which is the basis of the whole soft and hard bonded board FPC. The electrical performance of the soft and hard bonded board FPC is determined by it. Other auxiliary materials are only used to assist installation and adapt to the use of the environment.

Contact: Ms.Huang

Phone: 15023181892(微信同号)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA