Overlap of pads

1. The overlap of pads (except the one affixed to the surface) means the overlap of holes. In the drilling process, the drill bit will be broken because of multiple drilling in one place, resulting in hole damage.

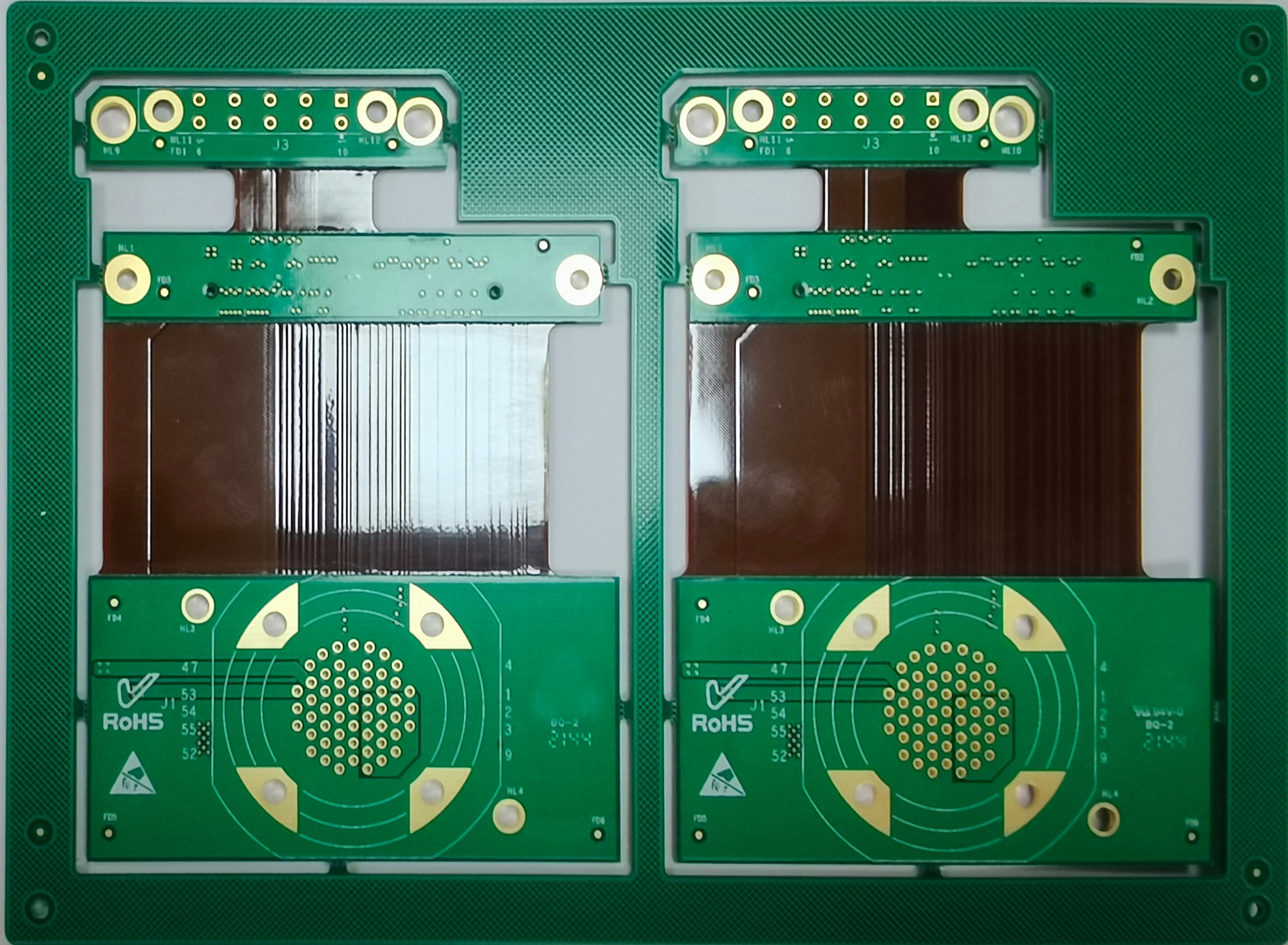

2. The overlap of two holes in the FPC of the multi-layer flexible circuit board, such as one hole for the isolation plate, the other hole for the connection plate (flower solder plate), so after drawing the film, it is shown as the isolation plate, resulting in scrap.

Two. Graphic layer abuse

1. Some useless connections were made on some graphic layers. FPC board was originally a four-layer flexible circuit board but designed more than five layers of lines, resulting in misunderstanding.

2. Save trouble in design. Take Protel software as an example to draw the lines existing in all layers with Board layer, and draw the marking lines with Board layer. Therefore, keep the graphic layer complete and clear when designing.

3. Violation of conventional design, such as component surface design in the Bottom layer, welding surface design in the Top, causing inconvenience.

Three. The random placement of characters

1. SMD pads for character cover bring inconvenience to on-off test and component welding of printed board.

2. The design of characters is too small, resulting in screen printing difficulties, too large characters overlap each other, it is difficult to distinguish.

Four. Single-sided pad aperture setting

1. Single-sided pads generally do not drill holes. If drilling holes need to be marked, their aperture should be designed as zero. If the values are designed so that the hole coordinates appear at this location when the borehole data is generated, the problem arises.

2. Single side pad such as drilling should be specially marked.

Five. Draw the pad with the filling block

Drawing pads with filler blocks can pass DRC inspection when designing the circuit, but not for processing. Therefore, the solder block can not directly generate solder blocking data. When applying solder blocking agent, the filling block area will be covered by solder blocking agent, resulting in welding difficulty of the device.

Electric formation is also flower pad and wire

Because the power supply is designed as a flowered pad, the stratum is the opposite of the image on the actual printed board, and all the lines are isolated lines, which should be very clear to the designer. Here, by the way, care should be taken when drawing isolation lines for groups of power sources or fields, so as not to leave gaps that would short-circuit the two groups of power sources or cause an area blockade of the connection (so that a group of power sources is separated).

Seven. The definition of processing level is not clear

1. Single-sided flexible CIRCUIT board FPC board is designed in the TOP layer, if you do not add instructions and positive and negative, maybe the produced board is installed on the device and not good welding.

2. For example, a four-layer FPC board is designed with TOP MID1 and MID2BOTTOM four layers, but it is not placed in such a sequence during processing, which requires clarification.

8. Too many filling blocks in the design or filling blocks with extremely thin lines

1. The optical drawing data is lost, and the optical drawing data is incomplete.

2. Because filling blocks are drawn one by one with lines during light drawing data processing, the amount of light drawing data generated is quite large, which increases the difficulty of data processing.

Nine. The pad of surface mount device is too short

This is for the on-off test, for too dense surface mount device, the spacing between the feet is quite small, the pad is also quite fine, the test needle installation, must be up and down (left and right) staggered position, such as pad design is too short, although does not affect the device installation, but will make the test needle is not wrong.

X. the spacing of large area grid is too small

The edge between the grid lines that constitute a large area is too small (less than 0.3mm). In the process of printed board manufacturing, a lot of broken film is likely to be attached to the board after the mapping process, resulting in wire breakage.

11. Large area of copper foil is too close to the outer frame

The distance between large copper foil and outer frame should be at least 0.2mm, because when milling out the shape, such as milling to the copper foil, it is easy to cause the copper foil warping and solder resistance shedding problems caused by it.

12. The shape of the frame design is not clear

Some customers have designed contour lines in Keep layer, Board layer and Top over Layer, and these contour lines do not coincide, which makes it difficult for PCB manufacturers to determine which contour line to take as the criterion.

13. Uneven graphic design

During graphic electroplating, the coating is not uniform and the quality is affected.

14. Apply grid line when the copper area is too large to avoid blistering when SMT

Contact: Ms.Huang

Phone: 15023181892(微信同号)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA