What is the FPC line of flexible circuit board

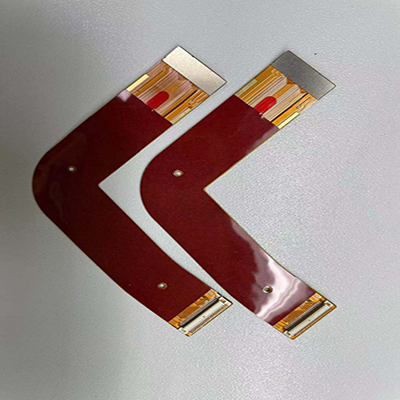

Speaking of FPC flexible circuit board line, you must know or familiar with FPC flexible circuit board line is what? Flexible PCB FPC line according to the feature points, can be divided into a lot of kinds, such as flexible circuit board FPC antenna, flexible circuit boards, flexible circuit board FPC FPC wiring, touch screen ribbon cable capacitance screen, such as flexible PCB FPC line is one of them, said popular point, flexible circuit board FPC row line is can be bent in a certain degree in the connection of the quad.

Ii. Functions and uses of FPC line of flexible circuit board

The function of FPC line is to connect two related parts or products. Now, many products are used to line, because it has a certain flexibility, in the printer, mobile phone, notebook and many other products have used flexible CIRCUIT board FPC line. FPC line manufacturers are mainly concentrated in the Pearl River Delta region, which is headed by Shenzhen.

Composition and parameters of FPC layout of flexible circuit board

FPC line of flexible circuit board is a kind of FPC, so its composition is the same as that of FPC. The FPC is typically long and designed with pluggable needles at both ends that can be directly attached to the connector or welded to the product. The middle is generally the line, because the FPC line of the flexible circuit board needs a certain flexibility, therefore, the base material is generally calendered copper, tortuous resistance, flexible.

Layout parameters:

The minimum line width line spacing is 3mil/3mil.

Minimum wire hole finished product up to 0.15mm.

FPC wiring process of flexible circuit board

The surface treatment process used for FPC line of flexible circuit board is usually gold immersion and occasionally oxidation prevention. But the anti-oxidation process can not withstand high temperature, the environmental bearing capacity is worse than the gold sink, the two prices are similar, therefore, most of the gold sink process. In addition, there are tin plating and tin spraying process, but FPC temperature is generally below 280 degrees Celsius, and tin spraying will have more than 300 degrees Celsius temperature, and tin paste hardness is smaller, so it is rarely used.

Advantages and disadvantages of FPC layout of flexible circuit board

Advantages:

FPC layout of flexible circuit board can greatly reduce the volume and weight of electronic products, suitable for electronic products to high density, miniaturization, high reliability development needs. Therefore, FPC line of flexible circuit board has been widely used in aerospace, military, mobile communications, portable computers, computer peripherals, PDA, digital cameras and other fields or products. In addition, it can be arranged according to the spatial layout requirements, and can be moved and expanded in three-dimensional space, thus achieving the integration of component assembly and wire connection.

Disadvantages:

Cost should be the most important consideration in the production process. Since the flexible FPC is designed and manufactured for special applications, the initial circuit design, wiring and photographic plates are expensive. Unless there is a special need to use the flexible circuit board FPC line C, usually in a small number of applications, it is best not to use. In addition, since a lot of effort has been put into doing it, the maintenance of late is also essential, so tin welding and rework need to be trained personnel operation.

Flexible CIRCUIT board FPC line storage

Unlike other products, FPC lines of flexible circuit boards are not in contact with air and water. So how do we store this product correctly? Believe that read the following content, we will find the answer.

First of all, the vacuum of the FPC line of the flexible circuit board can not be damaged. When packing, a layer of bubble film needs to be surrounded on the side of the box. The water absorption of the bubble film is better, which plays a very good role in moisture-proof.

Secondly, after sealing the box must be separated from the wall, stored away from the ground in a dry and ventilated place, but also avoid sunlight. The temperature of the warehouse is best controlled at 23±3℃, 55±10%RH. Under such conditions, PCB boards with surface treatment such as gold, electrogold, tin spraying and silver plating can generally be stored for 6 months, and PCB boards with surface treatment such as silver, tin and OSP can generally be stored for 3 months.

Polly peak circuit board as a professional flexible PCB FPC ribbon cable manufacturers, we are in the direction of the digital camera, car satellite positioning device, liquid crystal TV, notebook computer, medical instrument, intelligent robot, mobile phone and so on are involved in the communication field and research and development, thank you very much for support of numerous customers to polly peak, willing to work with us hand in hand advance together, Welcome more customers to negotiate cooperation.

Contact: Ms.Huang

Phone: 15023181892(微信同号)

Tel: 0755-23289186

Email: sales@fpcblf.com

Add: xingye road,14th,bao'an shenzhen city CHINA